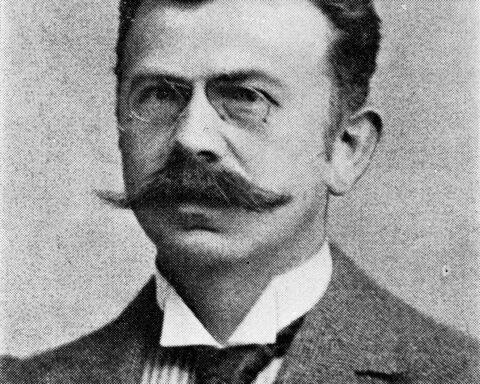

Vlad Batkhin, founder and CEO of Voltcore, discusses Voltcore’s approach to innovation. He highlights adapting to evolving customer needs and their vision for a sustainable future.

Can you provide a brief description of your company?

Voltcore is a Luxembourg-based smart materials and climate-tech start-up that develops and implements the technology of heated conductive filament and various derived products. This groundbreaking method is more sustainable than conventional fluid or metal-based heating systems. Our company aims to deliver high-quality, affordable, and eco-friendly heating solutions for homes and businesses, leveraging scientific research and advanced polymer nanocomposites. Heating is a significant component of global energy consumption, accounting for approximately 50% of the total final energy use. This makes heating the largest energy end-use sector, surpassing for example transportation. Voltcore is revolutionizing heating with its innovative conductive filament. This ultra-thin and flexible polymer wire delivers comfortable warmth much more efficiently than traditional methods. We help fight climate change through the new generation of heating materials to ultimately economize energy and reduce co2 emissions.

How are you adapting to the evolving expectations of your customers?

We are focused on adapting to the growing expectations of our customers by incorporating our suggestions into their products. By embracing innovative technologies and staying ahead of industry trends, we ensure our offerings meet the highest standards of quality and efficiency. Voltcore’s synthetic polymer wire provides a smart and eco-friendly heating solution for multiple sectors, including civil and industrial engineering, green energy, automotive, agriculture, construction, renovation, and textiles. Unlike traditional systems that rely on metal, liquid, or carbon film, our technology uses fewer natural resources and cuts down on air pollution and greenhouse gas emissions. Additionally, the wire is long-lasting, recyclable, and fire-safe. It blends effortlessly into any design without sacrificing visual appeal. Our dedication to sustainability goes beyond the product itself, supporting a greener economy and enhancing quality of life. Moreover, the technology can significantly boost the efficiency of electric vehicles in cold climates by extending battery life and lowering dependence on fossil fuel-powered grids during winter peaks. Our solution presents a strong case for businesses aiming to enhance sustainability, reduce costs, and improve performance.

“Innovative technologies and a focus on sustainability drive our mission to redefine heating solutions for a greener future.”

What is your company's vision for the next 5 years?

We already run our industrial filament production. In the next months, we plan to organize industrial processing into textiles and laminates at our partners’ facilities and start sample sales and pre-orders for industrial volumes. In winter 2024-2025, our main goal is to run testing in real conditions. From 2025 to 2027, we intend to reach TRL-9 and MRL-9. This means our technology will be in its final form, proven in real-world operations, and our production process will be fully qualified. We also plan to launch our first-of-a-kind factory to offer our products to the European and American markets. By 2027, we aim to become the most preferred industrial standard for oriented heating laminates, implement our technology in key industries and applications, and secure our position with key clients.