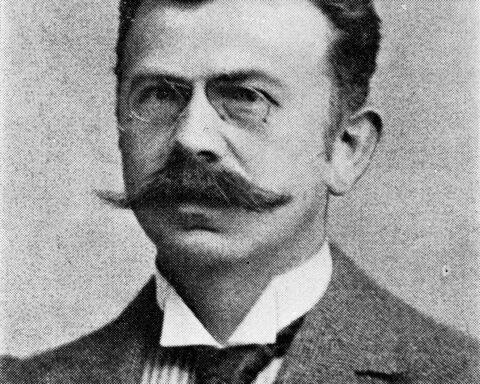

Michel Thein, Managing Director of Solarcells Luxembourg, discusses the company’s role as the only producer of high-quality photovoltaic panels in Luxembourg. He explains how Solarcells is addressing customer concerns about low-quality imports, its commitment to innovation, and its vision for expanding production while supporting national energy independence.

Can you provide a brief description of your company?

Solarcells Luxembourg is the only producer of high-quality photovoltaic panels in Luxembourg. Since our ramp-up in early 2024, we have produced about 20,000 panels. Our production process starts from a single cell, which we solder together into a string of half-cells and then laminate into a panel with a total of 108 half-cells. Our production line is approximately 100 meters long, and we ensure the quality of our final product at five separate quality control checkpoints. Our operators are specifically trained to perform these checks, guaranteeing that only the highest quality panels leave our factory to be installed by the end consumer. Currently, we have a small but very dedicated team of five production operators and have installed about 3 megawatts of panel capacity, which is equivalent to the consumption of about 800 households in Luxembourg. As such, we are a major actor in decarbonizing our local energy mix.

How are you adapting to the evolving expectations of your customers?

Right now, our focus is on educating the customer. Currently, customers are largely unaware of the dangers that some low-cost, low-quality panels can pose. It is no secret in the industry that most of the panels installed in the last two to three years will have to be replaced in the coming five years. Knowing that customers bought the product with the intention of generating revenue for up to 25 years, this is bad news for many who favored price over quality. Customers can visit our factory and learn firsthand what makes the difference. Many leave quite shocked. We are currently certifying and validating our production process with a European specialized laboratory to offer even greater power and efficiency for our customers.

“It is no secret in the industry that most of the panels installed in the last two to three years will have to be replaced in the coming five years.”

What is your company’s vision for the next five years?

Currently, we produce 150 panels in one eight-hour shift. We aim to expand by adding a second shift to increase our capacity. Furthermore, we will continue to be a key player in the industry landscape in Luxembourg and an inspiration to those who believe it is no longer possible to produce in Europe. We will keep innovating and following the market with ever-higher watt-peak numbers. We will uphold our values and offer the highest quality possible for our customers, all made right here in Luxembourg. We will continue to support a local market of suppliers that sustain us and remain a crucial actor in our national energy independence.